Introduction

We’re thrilled to announce the successful completion of the SteelSmart Minimum Viable Product (MVP)! This marks a significant milestone in our mission to improve carbon emission monitoring and management within the steel industry, paving the way for more sustainable and efficient operations. SteelSmart combines cutting-edge IoT technology, a robust cloud-based backend, and an intuitive user interface to deliver real-time data, actionable insights, and streamlined maintenance management.

The Challenge

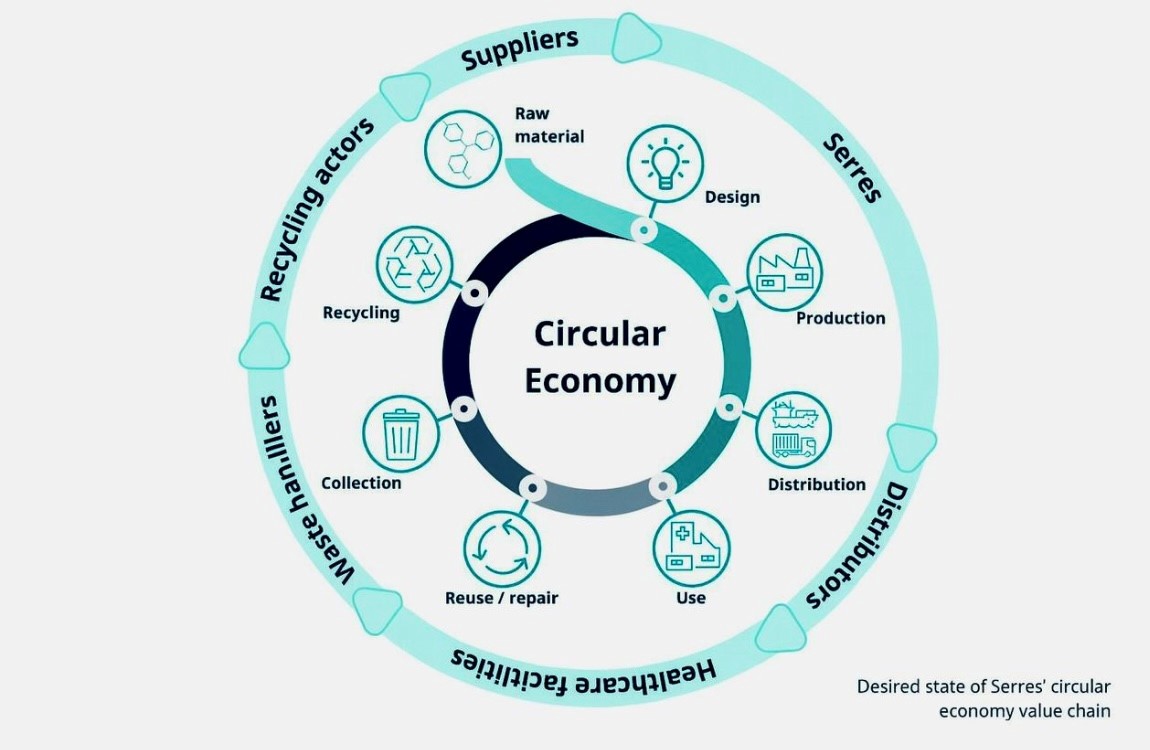

The steel industry faces increasing pressure to reduce its environmental impact. Traditional methods of monitoring and managing carbon emissions are often manual, time-consuming, and lack the real-time visibility needed for effective decision-making.

Our Solution: SteelSmart

SteelSmart offers a comprehensive solution that addresses these challenges by leveraging the power of IoT and cloud computing. Our MVP includes:

- IoT Device Prototype: We’ve developed a physical prototype using the Arduino Wemos D1 Mini and the SCD40 sensor to accurately measure carbon emissions, temperature, and humidity. This device seamlessly connects to a Wi-Fi network and publishes data to Azure IoT Hub using MQTT.

- Azure IoT Hub Integration: The Azure IoT Hub acts as a central message hub, securely receiving data from the IoT devices and routing it to our backend services.

- Real-Time Data Processing: A dedicated service deployed as an Azure WebJob subscribes to the IoT Hub, processes the incoming data, and stores it in a database for analysis and reporting.

- Intelligent Notifications: The system automatically generates notifications for relevant users when sensor data exceeds predefined thresholds, enabling proactive intervention and preventing potential issues.

- Maintenance Management: SteelSmart facilitates the creation and management of maintenance events, ensuring that equipment is properly maintained and that potential problems are addressed promptly.

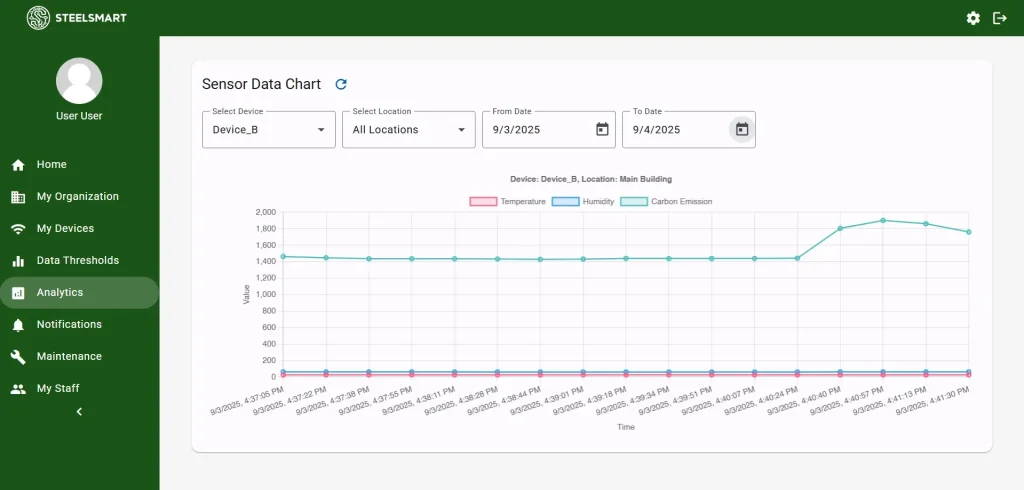

- User-Friendly Interface: Our Angular-based frontend application provides an intuitive and easy-to-use interface for users to:

- Start and stop sensors remotely.

- Set sensor reading intervals.

- View real-time and historical sensor data through interactive charts.

- Manage maintenance tasks and user assignments.

- Receive and manage notifications.

Key Features and Benefits:

- Real-Time Data Visibility: Gain instant access to critical environmental data, enabling informed decision-making.

- Proactive Alerting: Receive timely notifications when thresholds are exceeded, preventing costly downtime and environmental incidents.

- Streamlined Maintenance Management: Efficiently schedule, assign, and track maintenance tasks, ensuring optimal equipment performance.

- Improved Sustainability: Reduce carbon emissions and minimize environmental impact through data-driven insights and proactive management.

- Scalability and Reliability: Built on the Azure cloud platform, SteelSmart is designed for scalability, reliability, and security.

What’s Next?

The successful completion of the SteelSmart MVP is just the beginning. We’re committed to further developing and enhancing the platform to meet the evolving needs of the steel industry. Our next steps include:

- Expanding the range of supported sensors and data types.

- Implementing advanced analytics and predictive maintenance capabilities.

- Integrating with other enterprise systems.

- Scaling the platform to support larger deployments.

Call to Action:

We invite you to learn more about SteelSmart and how it can help your organization achieve its sustainability goals. Contact us today to schedule a demo and discuss your specific requirements.